KROOSH screeners provide solutions for a wide range of industrial processes, primarily the ability to efficiently screen hard-to-screen products such as wet and sticky bulk materials, as well as suspensions and polydisperse slurries with particle sizes from 15 microns to 30 mm.

It’s well-known that screens are different, and, among other things, it is possible to distinguish such types as:

KROOSH screens are related to vibrating screens, but, at the same time, they are fundamentally different from them. Usually, when talking about vibrating screens we mean a standard single frequency vibrating machine. KROOSH screeners are multi-frequency vibrating screeners.

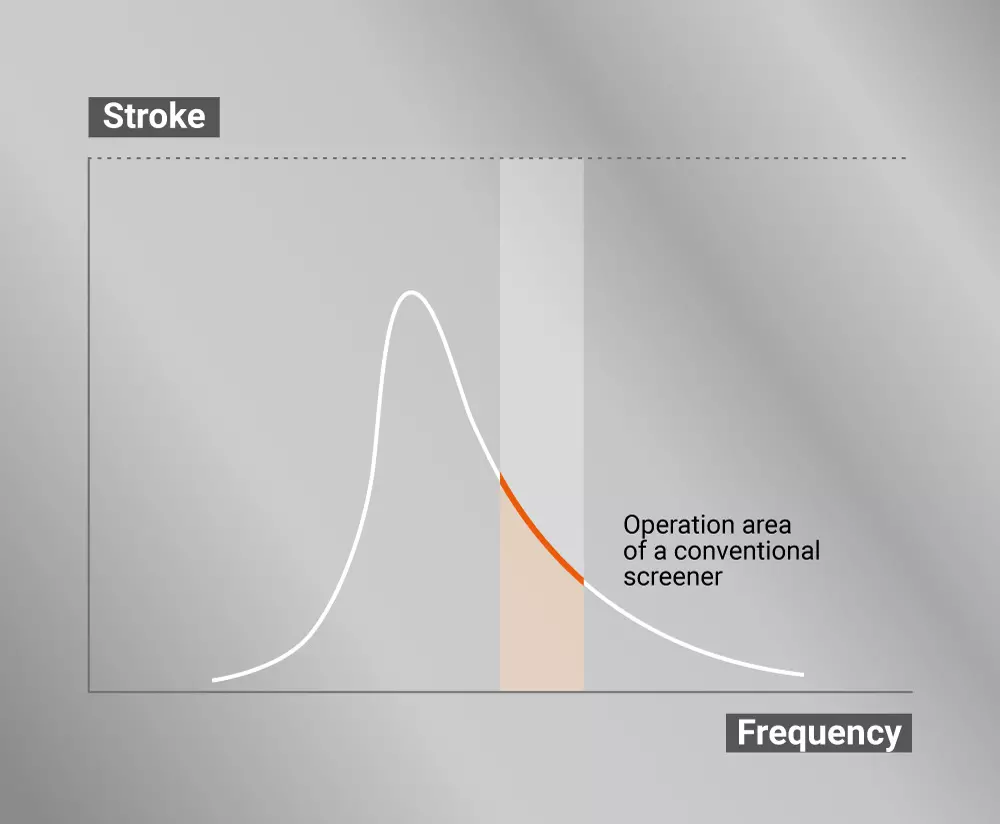

The main idea of operation of a conventional vibrating screen is that the vibration motor excites the screen mesh transmitting vibrations either to the screen body or directly to the mesh.

Screen vibration energy is important for screening performance:

The acceleration of the screen mesh of a single-frequency screener is very small and is more or less equal to the acceleration of the screener body i.e. a conventional (single-frequency) vibrating screener the amplitude of the body and the amplitude of the screen mesh are equal to each other and they are approximately 4-5 mm. This not only leads to clogging of the screens, but also - compared to multi-frequency screens - reduces the specific productivity of the equipment.

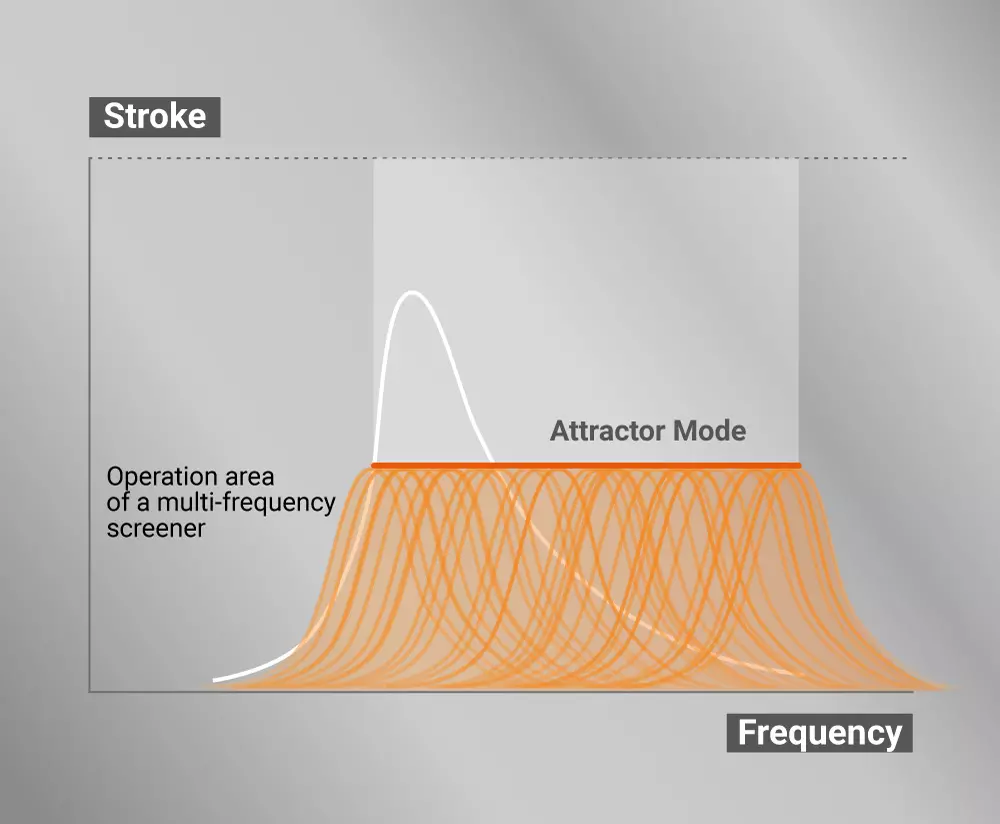

The main idea of KROOSH screeners is that single-frequency oscillations of the motor or screener’s body are converted into multi-frequency oscillations of the screen mesh with the help of a special mechanical device.

Please, have a look at how the same products are screened by a conventional vibrating screener and by a KROOSH multi-frequency screener.

KROOSH technology is based on the principle of influencing on a granular medium feeding in a screener with a continuous frequency spectrum corresponding to the frequency spectrum of this particular granular body.

As a result, the granular material gets the properties of a liquid. Outwardly, it looks like the movement of a turbulent fluidized layer of bulk material along the mesh. In this state, the segregation phenomenon is sharply activated in the layer, and small particles in a very short time pass through the layer to the screen mesh and then through the mesh apertures.

We developed the special mathematical model which adjust the following screen parameters:

Frequency spectrum is responsible for the self-cleaning of the screen mesh, for interacting with the material on the screen mesh and for its rapid mixing in order to quickly separate the layers.

Screen vibration energy is important for screen performance. The combination of a wide frequency spectrum and a large amplitude of screen mesh vibrations provide energy transfer to the material layer, which is much higher than the energy on conventional screens. This allows you to get a significant increase in the performance of a multi-frequency screener comparing to conventional screeners.

Thus, the developments of our team of scientists have made it possible to create a unique type of equipment for screening & sizing of hard-to-screen products with high quality and efficiency.